By: Adam Glasglow

This is Part 1 of a 3-part series: Crack the Code for Plastics Recycling with Again Technologies Consulting

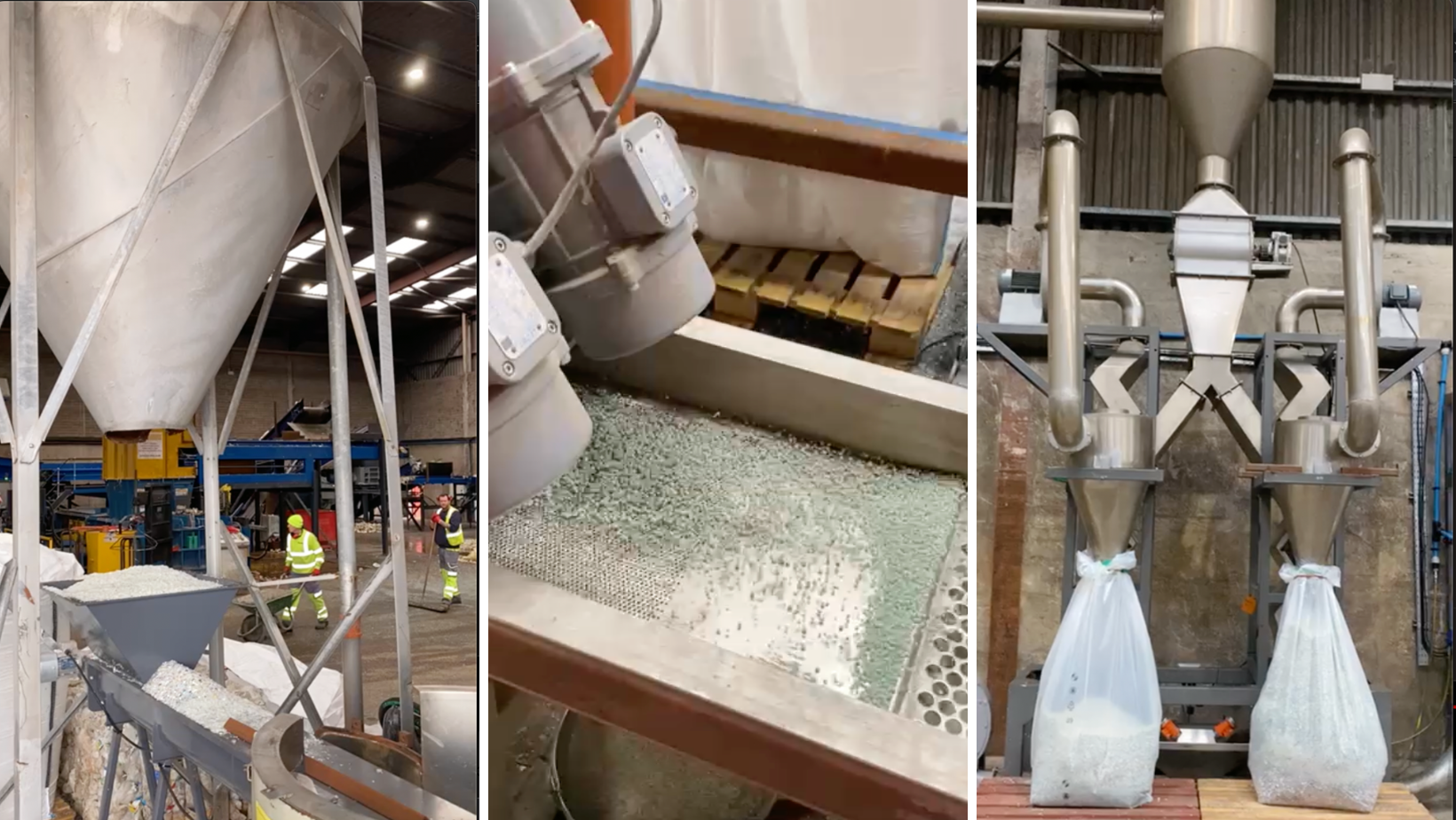

A common misconception in plastics recycling is that feedstock—the plastic waste needed for recycling—is readily available and easy to come by. However, the way garbage and plastic waste is collected, especially in the United States, makes this first essential step difficult, as each municipality handles garage collection and recycling differently. Therefore, it’s important to have strong relationships with collectors and material recovery facilities (MRFs)—like the relationships Again has built over decades—to understand what’s possible.

A client came to us to understand how to start advanced recycling. We determined right away that this client needed large amounts of polypropylene and polyethylene—or feedstock—to begin their project. This meant they couldn’t just work with recycling plants to source plastic waste; instead, they needed to start further upstream with garbage collection. Then, that garbage would need to be sorted to secure a reliable amount of polypropylene and polyethylene to start advanced recycling.

Again Technologies will work with companies to:

- Identify the most efficient and reliable raw material streams for mechanical or advanced recycling projects. Again’s presence in both the US and Europe guarantees more raw material streams can be considered. Raw material and feedstock will either come directly from recycling plants or further upstream via garbage collection.

- If working further upstream with garbage collection, Again will provide a study of how much plastic waste, or polypropylene and polyethylene, the garbage stream will yield to ensure that the stream is viable. This can help bring on additional stakeholders very early on in a project.

Identifying the raw materials and feedstock for mechanical or advanced recycling is just the first step. Read Part 2 of this series to understand what’s next: Contracting and setting up equipment.

Crack the Code for Plastics Recycling with Again Technologies Consulting

By: Adam Glasglow Recent studies about plastic recycling tell us it’s impossible, or a “dead-end street”1. But Again Technologies and the clients we work with

Part 2: Why Companies Need to Bring in Experts to Contract and Set Up Recycling Equipment

By: Adam Glasglow This is Part 2 of a 3-part series: Crack the Code for Plastics Recycling with Again Technologies Consulting Not all recycling equipment

Part 3: How to Secure Revenue Streams to Start Your Company’s Recycling Project

By: Adam Glasglow This is Part 3 of a 3-part series: Crack the Code for Plastics Recycling with Again Technologies Consulting When it comes to